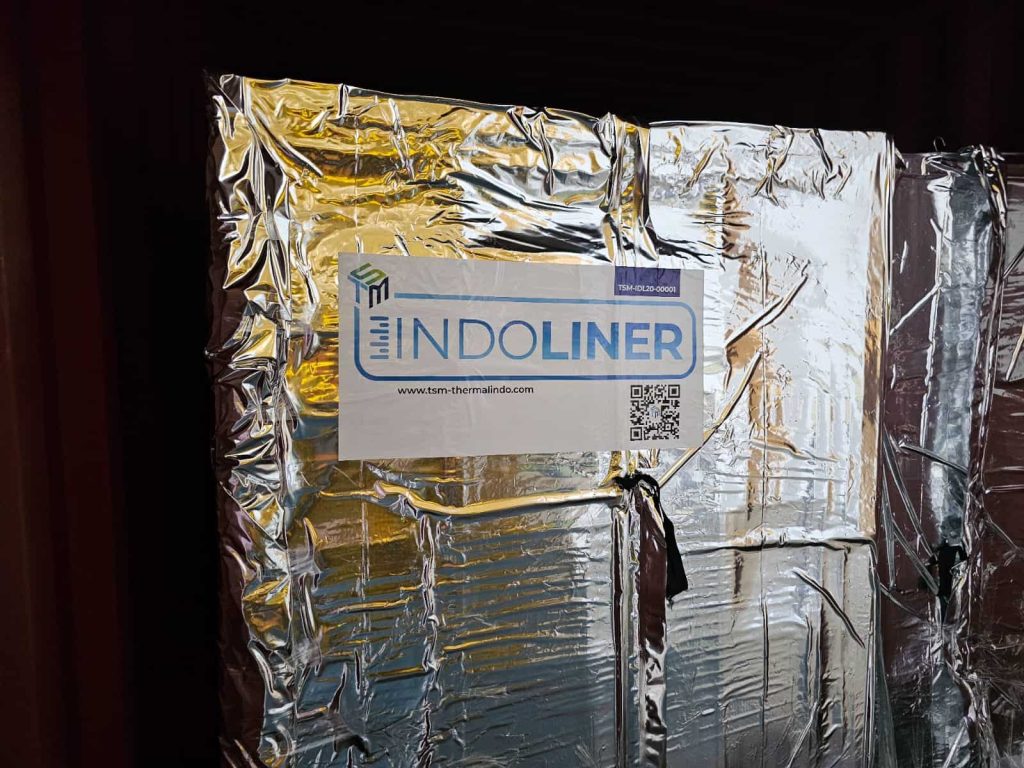

In industrial settings, maintaining optimal temperatures is crucial for ensuring the efficiency and reliability of various processes. This is where thermal insulation plays a significant role. Thermal insulation refers to the materials and techniques used to reduce the transfer of heat between objects with different temperatures. Here, we explore the importance of thermal insulation in industrial environments.

First and foremost, thermal insulation helps conserve energy by minimizing heat transfer. In facilities such as manufacturing plants, warehouses, and refineries, there are often significant temperature variations between indoor and outdoor environments. Without proper insulation, heat can escape during cold weather or infiltrate during hot weather, leading to increased energy consumption for heating and cooling systems.

Moreover, thermal insulation enhances process efficiency by maintaining consistent temperatures within equipment and pipelines. For example, in chemical processing plants, maintaining specific temperatures is critical for chemical reactions to occur optimally. Insulating equipment and pipelines help prevent heat loss or gain, ensuring that processes run smoothly and efficiently.

Additionally, thermal insulation contributes to safety in industrial environments. Many industrial processes involve high temperatures, which can pose risks to personnel and equipment if not properly controlled. Insulating equipment and structures help prevent heat-related accidents and protect workers from burns or other injuries.

Furthermore, thermal insulation can extend the lifespan of equipment and infrastructure by reducing thermal stress. Rapid temperature changes can cause expansion and contraction of materials, leading to mechanical strain and potential damage. By providing a buffer against temperature fluctuations, insulation helps minimize thermal stress and prolong the life of industrial assets.

In summary, thermal insulation plays a crucial role in industrial settings by conserving energy, enhancing process efficiency, ensuring safety, and extending the lifespan of equipment and infrastructure. Investing in quality insulation materials and proper installation can yield significant benefits in terms of cost savings, operational efficiency, and risk mitigation.